![]() Phone: 605-554-1911 | Email : [email protected]

Phone: 605-554-1911 | Email : [email protected]

Play With Your Food: Clean Brass With Rice

Jul 26, 2016

Written By - Greg Dykstra

© Copyright 2009 - Present - Primal Rights Inc

ALL RIGHTS RESERVED

No part of this website or any of its content may be reproduced, distributed, or transmitted in any form or by any means without the express prior written permission of Primal Rights, Inc

There are many ways to clean brass.

Cleaning your brass is a necessity. Foreign material in or on our cases can cause all kinds of problems. Damage to expensive reloading dies, damage to rifles, and various other issues can arise if proper care is not taken. Historically, shooters tumbled their brass in walnut or corn cob media using vibrator tumblers. This method works fairly well and has long since been the "standard" method. In recent years, a couple new technologies were explored. Ultrasonic cleaning was first, and used the power of ultrasonic transducers to "explode" the surface of the brass clean. Next came using a rotary tumbler, water, dish soap, and stainless steel pins to clean the brass. I have used each of the aforementioned methods, and in each instance I was left with the feeling that there is much room for improvement. A couple weeks ago while researching a completely unrelated topic, I was sent down a rabbit hole on the internet. You know how that is. Well I landed on an old forum post in some obscure corner of the internet, which outlined the use of rice and a vibratory tumbler to clean brass. That particular user hailed it as the best possible solution to the problem. The thought had never occurred to me before. I scooped up a handful of rice we had laying around and just by playing with it for a bit, was convinced that it may have merit. I had to try it. This article is the culmination of that testing.

Well what's the problem with the usual tumbling methods?

As I mentioned, I tried many ways of getting brass cleaned. Each time I was left feeling that it was quite imperfect. There are several problems and a whole laundry list of solutions to the various problems that you will encounter with each method. I'll spend a moment sharing my own thoughts on them here before we get started on the rice testing. I'm not going to spend a ton of time, as most of this is all pretty well known already.

Traditional Tumbling Media

I'm referring here to the walnut, corn cob, and various other traditional medias used in vibratory tumblers over the last century. The outcomes with these types of media are rather specific to the brand and type used. The gist of it is, you toss your brass in with a granular or flake-type media which will gyrate through a tumbler bowl and get clean. This process fairly slow, taking 4-8 hours or more to finish. It does accommodate large batches however. You can throw several hundred rifle cases in at a time. The main problem i had with the traditional media was the amount of toxic dust it generated. During tumbling, the media scrapes off the powder and primer residue left in the cases. This residue is laced with all kinds of undesirable substances that have a negative affect on human health. The actual tumbling doesn't cause much of an issue, as most tumblers have sealed lids, but when it came time to separate the media from the brass. This black soot was intermingled with the media, and tended to go airborne as any other dust would. I did not like that at all. I tried various additives which go into the media, and I must have tried a dozen different types of media over the years. This dust problem prevailed.

Ultrasonic Cleaning

Upon seeing pictures of super shiny like-new brass, I hopped on the ultrasonic bandwagon early. Again I was met with disappointment. I spent $500 on an ultrasonic cleaner only to discover that some pretty harsh chemicals were needed in order to make it actually clean the brass. Once I got my system down, I was able to get some very clean brass, and there was no dust. The problems arose from the cleaning chemicals needed to be "deactivated" or else the brass would be etched. Also it was a very small batch affair, only allowing about 60-80 pieces of 308 at a time. The wet process required a drying time before loading, and it turns out that an ultra-clean case neck was actually a bad thing from an accuracy/precision standpoint. I tried dozens of different chemicals and treatments for the water in the ultrasonic, as well as several different methods of solving the clean neck problem on the brass. Moly, graphite, etc. I just never could get the process to yield the results I was looking for on the target. Dealing with the dirty traditional media was much better than this.

Stainless Tumbling Media

Then along came using a rotary tumbler with dish soap and stainless steel pins. This seemed like the evolution I was waiting for. Again I was crippled by small batches of 100 or so, but the brass came out so clean you could eat off it. The most sparkly brass imaginable. That was in the "pro" column for sure. The con column came from the discovery of dinged and rolled case mouths and that same old "clean neck" issue. I have recently experimented with doubling the amount of stainless pins, as well as reducing the number of cases tumbled, and that seems to somewhat help the case mouth damage issue. It does not seem to remove it entirely however. A nicely trimmed and properly chamfered case will come out pretty beat up. Then there is the issue of it being a wet process, requiring the brass to completely dry before loading. Powder doesn't like wetness inside cases!

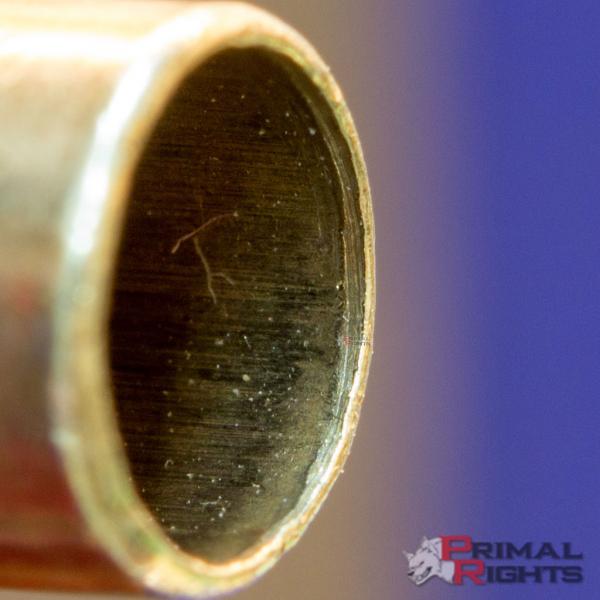

A close up of a .17 Remington case mouth after only 30 minutes in a Rebel 17 tumbler with 10lbs of stainless media and a batch of 100 cases. The tumbler was full to within 1/2" of top with water. This is the most gentle stainless tumbling method I've come up with, and it still damages the brass. The jagged rolled edge inside the case mouth is apparent. The effect is worsened by less media, more brass, and longer tumbling duration.

There is no denying one thing however: Stainless tumbling will clean your brass to a sparkly shine unlike anything out there, as is evidenced by the .17rem cases below. If you don't care about the case mouths being tore up, or leaving a nice finish inside your necks... stainless is certainly an option. I was able to maintain 1/2 MOA easily in all of my rifles when using the stainless method. However, when chasing 1/4 MOA or better performance, I noticed that bullet seating pressure was much more erratic with necks that were so clean. I had to sort my rounds into about 3 distinct batches based on seating pressure when seating bullets. The different batches absolutely produced different POI, which is something I verified on paper several times. Leaving some residue inside the case neck with traditional tumbling techniques never created that problem to such a degree.

Food products in my tumbler? Yep, I gave it a try.

The idea of using rice seemed a bit odd to me at first. After all, rice is meant for eating. However, upon examining the rice, it really did seem pretty logical that it would work. Rice is relatively hard, and has some edges on it. It also has absorptive qualities, which could help with removing sizing lubricant. That's really the main reason I tumble in the first place, is to get the Imperial Sizing Wax off the cases. Rice is ridiculously cheap, so it wasn't as if it was going to cost much to find out the truth of this.

I started out with some plain white rice we had on hand.

Rice is nice and clean, without much in the way of "powder" in it. I filled the tumbler up to the appropriate level with the rice and tossed in a couple hundred 6.5CM cases which had been recently resized. They were pretty dirty and of course completely covered in Imperial wax. I left them in there for about 3 hours, and imagine my surprise when I pulled the lid off. Below you can see a dirty cases on the right, and cases which tumbled in rice for 3hrs on the left. That is certainly good enough to get the job done. ... and the best part is I could grab that clean case and load it up immediately if I wanted to!

Next I tossed in a batch of 100 22-243win cases. This time I let them tumble overnight. I expect they were in there for about 12hrs before I pulled them out. These cases came out extremely clean.

To get the rice out of the case, you just hold it upside down against the vibrating bowl and the rice scurries out the neck... even on .22cal cases.

I did discover one nasty thing about using rice.

Rice is the perfect size for large flash holes. Each batch I did, produced about 90% of the cases that had rice lodged in the flash hole. This was pretty easy to fix, as rice is somewhat brittle. I used an old decapping rod I had laying around, snapped the rice kernel off, and poked it out of the flash hole with the decapping rod. It went pretty smooth really. Small flash holes didn't seem to have nearly as much of a problem.

The solution to the flash hole problem came in the form of using a different kind of rice. Using this rice almost completely alleviated the problem. There were still a few plugged flash holes, but only 5% or so rather than over 90%.

Here is the best rice I've found for this job!

Click this link to see the rice on amazon!

After about 1000pcs of brass through the tumbler, the rice was pretty well shot. After all of this tumbling, there was still not any "dust" buildup in the tumbler. It seemed to have all been completely absorbed by the rice. As you can see in the image above, the used rice had gone from a nice bright white to a gunmetal gray color. So far I have used rice to tumble .223rem, 22-243win, 22-243AI, 6BR, 6.5CM, 300BLK, 308win, and a few others. So far the only thing that was a complete no-go was .17 remington. The rice packs inside the cases tightly, and due to the tiny neck, it absolutely will not wiggle out. That happens within 10 minutes of being placed in the tumbler. It took me about 2 hours to get the rice out of all 100pcs of .17 rem I threw in there. Anything .22 cal and larger doesn't seem to pose any problems however.

Suffice it to say I was thoroughly impressed by the simplicity of this whole process. Dump rice in, dump brass in, tumble for 3-12hrs, remove brass... go load ammo. No more wet process, no more tortured case mouths, and no toxic dust. I kind of sat in amazement that this information hasn't been plastered all over the forums I frequent. It wasn't my idea. It was a very old idea actually. If memory serves, the forum post I read was from the mid-90's! I have since found this referenced in a few obscure reloading books as well. It really is a shame that stuff like this can be lost to time!

Consider this a public service announcement:

Rice is an excellent way to clean your brass!